Production Description

HY-FILLING 5 gallon water production line consists of empty bottle transferring, internal bottle brushing, auto de-capper, external bottle brushing, rinsing filling capping, light checker, neck shrinker, bagging, full bottle transferring and pallitizer, enabling full automatic intelligent production. The whole process is strictly controlled, which ensures the complete compliance with customer's local standards and regulations set up by their Health Department. During filling process, secondary pollution is strictly controlled, which makes it an ultra-clean production line. It's a most ideal, acknowledged and reliable automatic gallon water production line for companies and factories. This line is mainly used for filling pure water or mineral water of 3 & 5 gallon bottle.

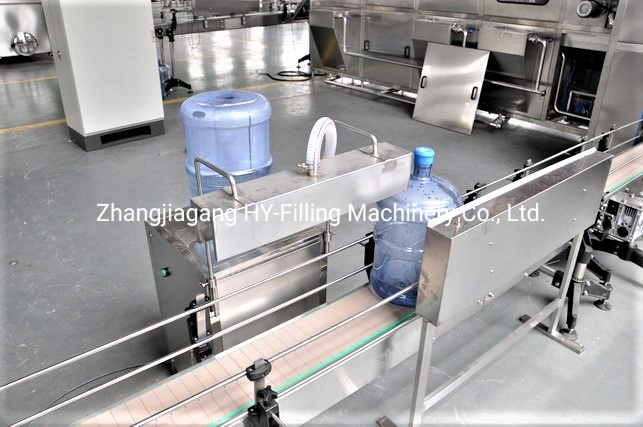

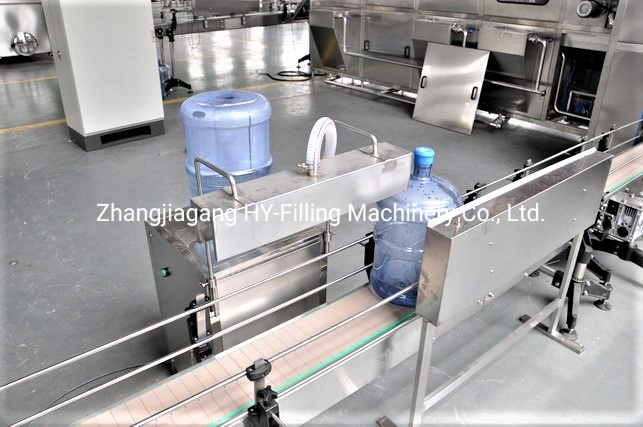

Details Images

5 Gallon Barrel Water Production Line

1.Filling Part

<1> 304/316 Stainless steel high precision filling nozzle

2.Main Machine Features

<1>Shape structure adopted concave and convex shape, perfect appearance also reduces the leakage.

HY-Filling

<1> Standardized workshop of total 30,000 square meters.

Certifications

Production packing

Packing type:

As usual, we adopt wooden case as package type. It's suitable for long-distance transport. According to customers' special demand, we could adopt sheet iron case and so on.

HY-Service

Installation and commissioning

HY-FILLING 5 gallon water production line consists of empty bottle transferring, internal bottle brushing, auto de-capper, external bottle brushing, rinsing filling capping, light checker, neck shrinker, bagging, full bottle transferring and pallitizer, enabling full automatic intelligent production. The whole process is strictly controlled, which ensures the complete compliance with customer's local standards and regulations set up by their Health Department. During filling process, secondary pollution is strictly controlled, which makes it an ultra-clean production line. It's a most ideal, acknowledged and reliable automatic gallon water production line for companies and factories. This line is mainly used for filling pure water or mineral water of 3 & 5 gallon bottle.

Details Images

5 Gallon Barrel Water Production Line

1.Filling Part

<1> 304/316 Stainless steel high precision filling nozzle

<2> Filling volume adjustable in fine rank, same liquid level after filling

<3> All 304/316 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean

<4> 304/316 stainless steel filling pump

2.Main Machine Features

<1>Shape structure adopted concave and convex shape, perfect appearance also reduces the leakage.

<2>The thickness of the stainless steel plate which used for 600bph is 3mm.

<3>Tank and the heating pipe in tank are removable which become more clean sanitation.

Flow chart :

Barrel uploader -->Decapping machine-->Leakage inspector-->External brusher-->Internal brusher-->Automatic Rinsing,filling,capping(3in1) machine-->Light checker-->Cap labeling machine-->Date printer-->Barrel lifter-->Barrel stacking machine

Company Profile

<3>Tank and the heating pipe in tank are removable which become more clean sanitation.

Flow chart :

Barrel uploader -->Decapping machine-->Leakage inspector-->External brusher-->Internal brusher-->Automatic Rinsing,filling,capping(3in1) machine-->Light checker-->Cap labeling machine-->Date printer-->Barrel lifter-->Barrel stacking machine

Company Profile

HY-Filling

<1> Standardized workshop of total 30,000 square meters.

<2> With a more than 30 professionals team to design and develop, is a key professional enterprise, which integrates development, research, design, manufacture, technology service and marketing.

<3> HY-Filling follows ISO9001:2000, CE Certificate , SGS , COC , TUV international quality management system. <4>The equipment will be tested and run for 24 hours before leaving the factory, to ensure the smooth working of water pipeline, and pneumatic, electrical and mechnical stability. <5>Professional installation team who are seasoned technician, Provide equipment quality installation services.

Certifications

Production packing

Packing type:

As usual, we adopt wooden case as package type. It's suitable for long-distance transport. According to customers' special demand, we could adopt sheet iron case and so on.

HY-Service

Installation and commissioning

After the equipments arrived buyer's workshop, the buyer should take it's place for each equipment according to the supplied layout; the seller will send the experienced technician to guide the installation and debugging and trail production, and fulfil the designed capability within the designed time. The installation, debugging and training is about 30-35 days

Training

The seller will supply technical training to the buyer. The training is includes: equipment structure and maintenance, control and operation. After training, the technicians of the buyer will grasp relevant operation and maintenance skills, and could adjust the technologies more skilled, and can deal with all kinds of malfunction in time.

After-sales service

1) After qualified of the equipment, the seller will supply one year guarantee, control system one year guarantee, free charge for wearing parts, and other spare parts with cost price. Within guarantee period, the technicians who accepted training should strictly obey the requirements asked by the seller to operate the equipments and maintenance, to find the common malfunctions and fault clearing in time; if the technicians of the buyer couldn't solve the problems themselves, the after-sales department will supply long range guide service by phone; if relevant measurements couldn't solve the problems, the seller will send the technicians to the buyer factory, clear the fault or relevant technical problems on site, the charges will reference to the installation and debugging charges.

2) After guaranteed, the seller will supply widely favorable technical support, after-sales service for the lifetime: favorable price for the wearing parts and other spare parts.