Laboratory Heating and Drying Industrial Drying Ovens for Testing

Application

Precise oven or cabinet dryers are mostly used for drying, baking, sterilization of non - volatile items, and heat treatment test for mining enterprises, schools, medical and scientific research. Especially for simultaneous drying of different kinds of polymers small quantities for drying materials for trial molding. They can also be applied in electronic engineering, electroplating, and pharmacy, paint baking, printing industries, etc. For preheating or drying related products.

Features

Provide a series of the stable and reliable precision oven, KOV precise oven inside the box dimension is divided into eight kinds of standard specifications, can meet various requirements.

Forced air supply circulation system and the special outlet design to ensure perfect humidity and temperature uniformity.

LED digital temperature controller, easy operation, and bring you a happy customer experience.

Air-exhausting Device is optional

Another ultra-high-temperature oven series can reach 500 º C is available upon customized.

| Specifications | |||||||||

| Model | KOV-50 | KOV-100 | KOV-200 | KOV-290 | KOV-500 | KOV-600 | KOV-720 | KOV-1000 | KOV-1800 |

| Interior size (W*H*D)mm | 400*350*350 | 450*500*450 | 600*600*600 | 600*950*500 | 800*1050*600 | 1000*1000*600 | 900*1000*800 | 1000*1000* 1000 | 1600*1400* 600 |

| Exterior size (W*H*D)mm | 1010*650* 760 | 1110*800* 1100 | 1260*900* 1100 | 870*1590* 640 | 1160*1760* 880 | 1360*1715* 880 | 1300*1750* 1000 | 1400*1750* 1200 | 1600*1940* 1200 |

| Capacity(KVA) | 3.5 | 3.5 | 4.5 | 4.5 | 6 | 6.5 | 7.5 | 8.5 | 9.5 |

| Power | AC220V±10% 1Φ 50Hz/60Hz | AC 380V±10% 3Φ4wire 50Hz/60Hz | |||||||

| Temp. range | 50 ºC~ 200 ºC( 300 ºC) | ||||||||

| Temp. constancy | ±1.0 ºC | ||||||||

| Temp. uniformity | ±2.0 ºC( 50 ºC~ 200ºC ) ±3.0 ºC( 101 ºC~ 200 ºC) | ||||||||

| Heat uptime | 50 ºC to 200 ºC within 50 min | ||||||||

| Interior material | Stainless steel plate | ||||||||

| Exterior material | Painted Stainless steel plate | ||||||||

| Insulation material | Glass wool | ||||||||

| Safety devices | No fuse breaker, over temp protection, ceramic fuse | ||||||||

| Accessories | Recorder, insolating layer | ||||||||

| Note: 1. We reserve the right to change specifications without prior notice 2. Customized sizes and configurations available | |||||||||

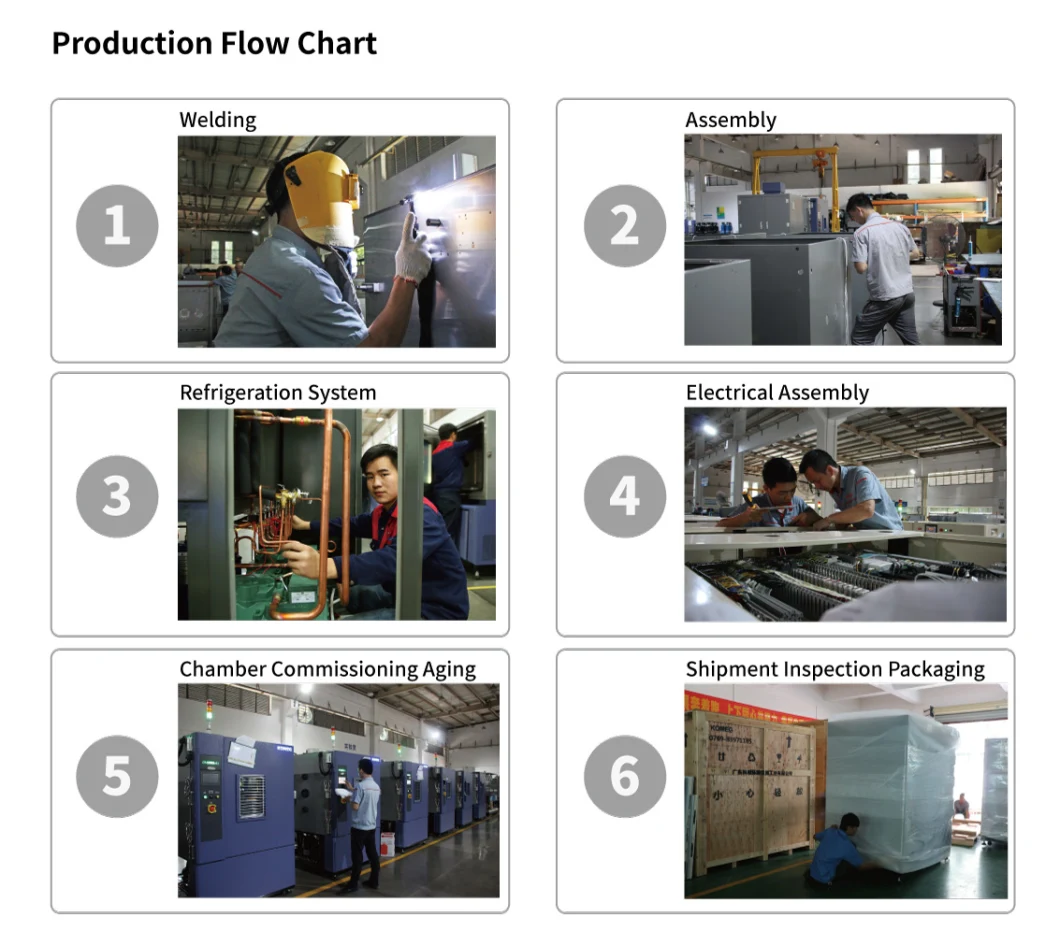

Packaging

Each set protected with resin fiber and PP film, then put into Strong wooden case with operation manual and video inside.

After-service

If you face any problems in the future during the testing process we promise we will give you a reply within 48 hours and the solution provide within 3 working days. We can offer operation video and English operation muanual. We can provide video-conference. If customers require on-site service, the transport and travel expense shall be borne by the customer.

Thank you for your time and patience!

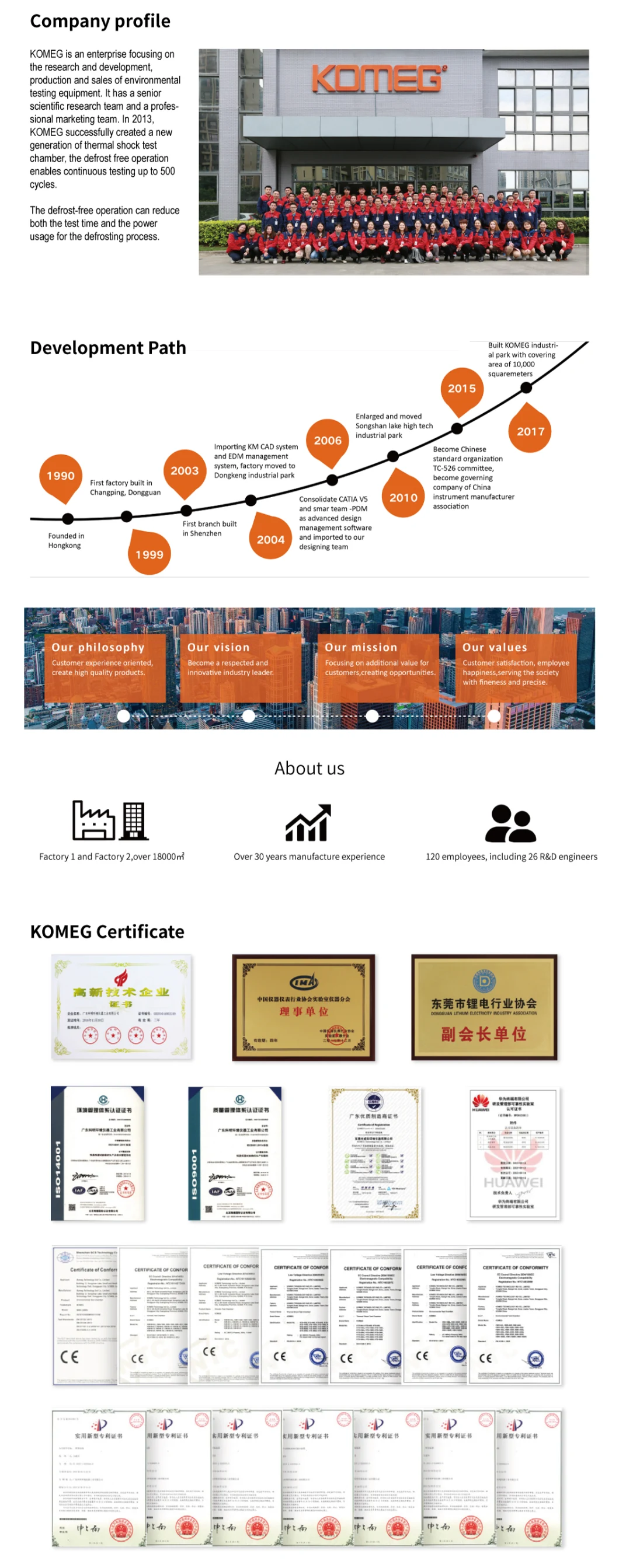

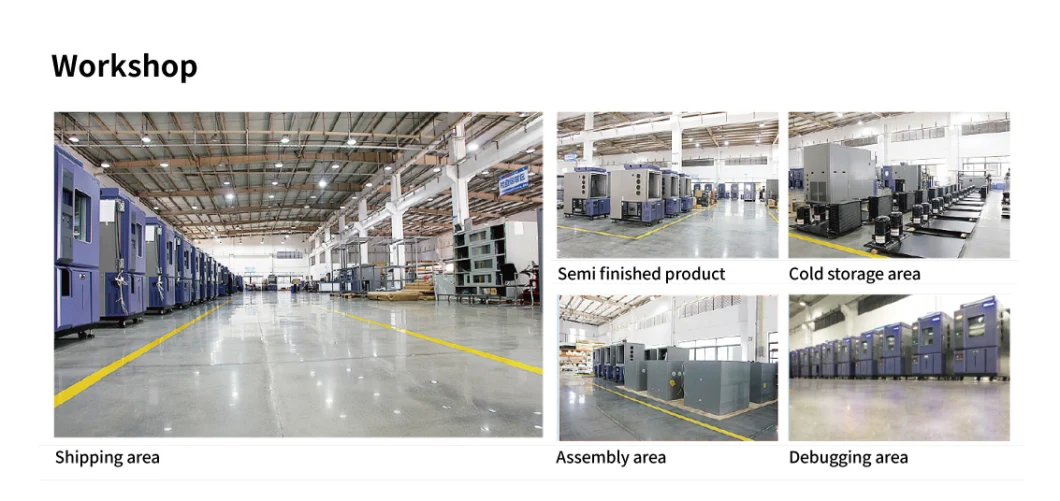

KOMEG welcomes you to inspect our factory at any time.

Besides this, we also supply Walk-in Chamber, Temperature and Humidity Chamber, Thermal Shock Chamber, Salt Spray Chamber, Drying Ovens, Free Fall Drop Tester, etc.