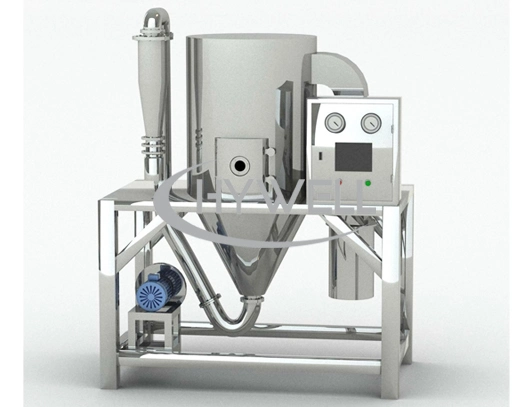

The air enters into the air distributor on the top of the dryer in the spiral form and uniformly after been filtered and heated, the material liquid Passing through the high-speed centrifugal atomizer on the top of the tower, it will rotate and be sprayed into the extremely fine mist liquid beads. Through the very short time of contacting the pure heat air, the materials can be dried into the final products by seconds. The final products will be discharged continuously from the bottom of the drying tower and from the cyclones. The waste gas will be discharged from blower. Hywell will design the bag filter to collect materials to reach 99.9%. If some materials will be environment pollution, It can design and supply the water scrubber.

LPG series high speed centrifugal spray dryer consists of air filter system and heating system, liquid transfer system, liquid atomizing, drying tower, air exhausting and material collecting, control system and so on, the feature for each system as bellow:

1.Air filtering system and heating system

Before the fresh air enter into the heater, it should pass through the Primary and Medium effect filter first, and then enter the heater for heating. For the heating method, there are electrical heater,steam radiator or gas furnace and so on. Which method to choose depends on the customer site conditions. To ensure the drying medium enter into the drying chamber with high purity, the heated air should go through the high temperature high efficiency filter (Optional) before enters the drying chamber.

2. Liquid transfer system

The liquid transfer system consists of liquid tank, pump and so on, as to ensure the liquid enter into the atomizer smoothly.

3. Atomizing system

The atomizing system consists of high speed centrifugal atomizer with inverter and so on.

The final dried powder from the high speed centrifugal atomizer is between 40-120 microns.

4. Drying tower system

The drying chamber consists of the spiral shell, hot air distributor, main tower and relevant fittings.

The Spiral shell and hot air distributor: the spiral shell and hot air distributor at the top of tower and it can regulate air flow rotation angle according to the specific condition to guide the air flow inside the tower effectively and avoid the material stick on the wall.

Drying tower: The inner wall is SUS mirror sheet, and welded by the arc welding. It have the insulation layer. The middle of tower have the manhole to view and be convenient to clean and maintain the tower. For the tower body cross interface, pipe elbow are arc butt design, reduce dead angle; sealed type. The main tower is equipped with air hammer, controlled by the pulse, and hitting the main drying tower timely as to avoid the dust stick on the wall.

5. Air exhausting and product collecting system

For the material collecting system, there are several types. Such as cyclone, cyclone + bag filter, cyclone+ bag filter +water scrubber and so on. The method is depending on the material property itself. For the filtering system for the outlet air, we have filter on request.

6. Control system

HMI+PLC, each parameter can be displayed on the touch screen. Every parameter can be controlled and recorded easily. but it also can use button to reduce client investment. HMI + PLC,

Attention to order

1. When order the LPG Series Laboratory Spray Drying Machine / Spray Dryer, Client need to supply the materials name.

2.When order the LPG Series Laboratory Spray Dryng Machinery / Spray Dryer, Client need to supply the materials characteristic that include materials HP, Maximum withstand temperature and so on.

3.When order the LPG Series Laboratory Spray Drying Machine / Spray Dryer, Client need to supply the materials primary moisture and final moisture (%).

4.When order the LPG Series Laboratory Spray Drying Machine / Spray Dryer, Client need to supply the treating capacity per hour.

5.When order the LPG Series Laboratory Spray Drying Machine / Spray Dryer, Client need to supply heating way, if it use steam heating, client need to supply the steam pressure and steam capacity.

6.When order the LPG Series Laboratory Spray Drying Machine / Spray Dryer, Client need to decide which kinds steel for machine-304 stainless steel or 316L stainless steel (Hywell also give suggestion for the stainless steel model base the materials HP).

Applications

Chemical Industry: Sodium fluoride(potassium),alkaline dyestuff and pigment, dyestuff intermediate, compound fertilizer, formic silicic acid, catalyst, sulphuric acid agent, amino acid, white carbon and so on

Food Industry: Fatty milk powder ,protein, cocoa milk powder, substitute milk powder, egg white(yolk), food and plant, oats, chicken juice, coffee, instant dissoluble tea, seasoning Sugar, corn syrup, corn starch, glucose, pectin, malt sugar, and etc.

Parameter:

The Main technical parameters is for reference. We also produce and design product as per customers' requirment:

About Us:

From drying machine, mixing machine to granulation machine, from unit machine to production line, we have them all. Hywell Machinery is a professional manufacturer of industrial dryer, powder mixer and granulation machine. Our flagship products include the drying oven, fluid bed dryer, belt dryer, vacuum dryer machine, rotary flash dryer, chamber drying machine, single dimensional powder mixer, three dimensional mixer, two dimensional mixer and high shear granulation machine, continuous granulator and so on. These high-performance machines have extensive applications within industries such as food, medicine and chemical. Sustained development and a strong emphasis on research and technology have bolstered our quality standards. we seek to achieve the highest level of customer satisfaction through professionally developed drying, mixing and granulation solutions. Hywell Machinery constant faith is providing perfect products to customer, excellenting service to customer !

Quality control

In order to ensure quality of product, we focus on user 's requirements and control improvement and enhancement quality of products .The quality assurance mainly focus on the processes of ensuring production readiness inspection, control of raw materials and components, process control, critical parts, important parts of quality control, assembly quality control, process control testing, measurement equipment control. Pay close attention to the implementation of the quality assurance work, strictly to three inspection system of self-checking, mutual inspection, special inspection. The key point of Quality assurance is focuses on critical parts, important parts of quality control, the quality standards required by ISO9000 quality control procurement documents in order to clarify its status and acceptance of quality standards for company's re-inspections ; For critical parts and important that the key processes of identification and corresponding technical documentation, control by "the implementation of key quality control process", and complete, accurate and complete original records. Difficulties in quality assurance is a special process control, quality assurance is mainly painting, has developed a special process (painting) process documents, take the appropriate technical measures, to quality assurance.

In the production process, we pay close attention to quality control of each process. Every component, every process was strictly controlled. Enhanced the quality inspection process, the establishment of the necessary quality control point, the process by a full-time staff and quality inspector for inspection and supervision. Improved testing procedures and operating instruction.

OUR SERVICES

Pre-sale service

We invite customers to visit our company and communicate on technical requirements face to face. we also can do test in our lab for free. and then we will use the testing parameter to design final machine to reach client requirement.

Sale service

Responsible for debugging the equipment according to customers' requirements of various technical data. Our engineers will train our customers about equipment features and operation key points to make sure the equipment running in the best condition.

After-sale service

We provide installation, debugging, maintenance, training and other services (Optional); Provide relevant technical data, equipment, software and related GMP certification materials.

Quality promise

Our company promises strictly operate the ISO9001 quality system certification standards and pharmaceutical equipment GMP audit requirements,promise we provide new equipment. Advanced technology,good quality. Equipment operation safe reliable, affordable, easy to maintain.

Equipment warranty period is one year, all the parts for the equipment choose well-known brand.During the warranty when equipment have problem in quality like equipment failure and damage, our company offer free maintenance or replacement.

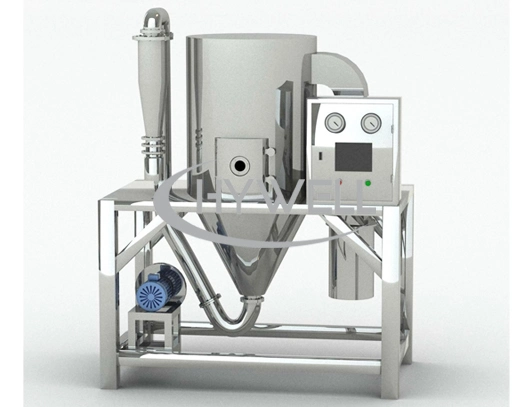

LPG series high speed centrifugal spray dryer consists of air filter system and heating system, liquid transfer system, liquid atomizing, drying tower, air exhausting and material collecting, control system and so on, the feature for each system as bellow:

1.Air filtering system and heating system

Before the fresh air enter into the heater, it should pass through the Primary and Medium effect filter first, and then enter the heater for heating. For the heating method, there are electrical heater,steam radiator or gas furnace and so on. Which method to choose depends on the customer site conditions. To ensure the drying medium enter into the drying chamber with high purity, the heated air should go through the high temperature high efficiency filter (Optional) before enters the drying chamber.

2. Liquid transfer system

The liquid transfer system consists of liquid tank, pump and so on, as to ensure the liquid enter into the atomizer smoothly.

3. Atomizing system

The atomizing system consists of high speed centrifugal atomizer with inverter and so on.

The final dried powder from the high speed centrifugal atomizer is between 40-120 microns.

4. Drying tower system

The drying chamber consists of the spiral shell, hot air distributor, main tower and relevant fittings.

The Spiral shell and hot air distributor: the spiral shell and hot air distributor at the top of tower and it can regulate air flow rotation angle according to the specific condition to guide the air flow inside the tower effectively and avoid the material stick on the wall.

Drying tower: The inner wall is SUS mirror sheet, and welded by the arc welding. It have the insulation layer. The middle of tower have the manhole to view and be convenient to clean and maintain the tower. For the tower body cross interface, pipe elbow are arc butt design, reduce dead angle; sealed type. The main tower is equipped with air hammer, controlled by the pulse, and hitting the main drying tower timely as to avoid the dust stick on the wall.

5. Air exhausting and product collecting system

For the material collecting system, there are several types. Such as cyclone, cyclone + bag filter, cyclone+ bag filter +water scrubber and so on. The method is depending on the material property itself. For the filtering system for the outlet air, we have filter on request.

6. Control system

HMI+PLC, each parameter can be displayed on the touch screen. Every parameter can be controlled and recorded easily. but it also can use button to reduce client investment. HMI + PLC,

Attention to order

1. When order the LPG Series Laboratory Spray Drying Machine / Spray Dryer, Client need to supply the materials name.

2.When order the LPG Series Laboratory Spray Dryng Machinery / Spray Dryer, Client need to supply the materials characteristic that include materials HP, Maximum withstand temperature and so on.

3.When order the LPG Series Laboratory Spray Drying Machine / Spray Dryer, Client need to supply the materials primary moisture and final moisture (%).

4.When order the LPG Series Laboratory Spray Drying Machine / Spray Dryer, Client need to supply the treating capacity per hour.

5.When order the LPG Series Laboratory Spray Drying Machine / Spray Dryer, Client need to supply heating way, if it use steam heating, client need to supply the steam pressure and steam capacity.

6.When order the LPG Series Laboratory Spray Drying Machine / Spray Dryer, Client need to decide which kinds steel for machine-304 stainless steel or 316L stainless steel (Hywell also give suggestion for the stainless steel model base the materials HP).

Applications

Chemical Industry: Sodium fluoride(potassium),alkaline dyestuff and pigment, dyestuff intermediate, compound fertilizer, formic silicic acid, catalyst, sulphuric acid agent, amino acid, white carbon and so on

Food Industry: Fatty milk powder ,protein, cocoa milk powder, substitute milk powder, egg white(yolk), food and plant, oats, chicken juice, coffee, instant dissoluble tea, seasoning Sugar, corn syrup, corn starch, glucose, pectin, malt sugar, and etc.

Parameter:

The Main technical parameters is for reference. We also produce and design product as per customers' requirment:

| Spray Drying Equipment | LPG-5 | LPG-25 | LPG-50 | LPG-100 | LPG-150 | LPG(200-11000) |

| Max evaporation(kg/h) | 5 | 25 | 50 | 100 | 150 | 200-11000 |

| Inlet temp(ºC) | ≤350 | ≤350 | ≤350 | ≤350 | ≤350 | ≤350 |

| Outlet temp(ºC) | ≤90 | ≤90 | ≤90 | ≤90 | ≤90 | ≤90 |

| Driving type of centrifugal sparyer | drived by compressedair | machanincal drive | ||||

| Rotation speed(r.p.m) | 25000 | 22000 | 21500 | 18000 | 18000 | 8820-15000 |

| Dia.of spray pallet | 50 | 102 | 108 | 108 | 150 | 180-340 |

| Dimension(m) | 1.8*0.93*2.2 | 3*2.7*4.26 | 3.7*3.2*5.1 | 4.6*4.2*6 | 5.5*4.5*7 | design acording to actual conditions |

| Powder recollection(%) | 95-99 | 95-99 | ||||

About Us:

From drying machine, mixing machine to granulation machine, from unit machine to production line, we have them all. Hywell Machinery is a professional manufacturer of industrial dryer, powder mixer and granulation machine. Our flagship products include the drying oven, fluid bed dryer, belt dryer, vacuum dryer machine, rotary flash dryer, chamber drying machine, single dimensional powder mixer, three dimensional mixer, two dimensional mixer and high shear granulation machine, continuous granulator and so on. These high-performance machines have extensive applications within industries such as food, medicine and chemical. Sustained development and a strong emphasis on research and technology have bolstered our quality standards. we seek to achieve the highest level of customer satisfaction through professionally developed drying, mixing and granulation solutions. Hywell Machinery constant faith is providing perfect products to customer, excellenting service to customer !

Quality control

In order to ensure quality of product, we focus on user 's requirements and control improvement and enhancement quality of products .The quality assurance mainly focus on the processes of ensuring production readiness inspection, control of raw materials and components, process control, critical parts, important parts of quality control, assembly quality control, process control testing, measurement equipment control. Pay close attention to the implementation of the quality assurance work, strictly to three inspection system of self-checking, mutual inspection, special inspection. The key point of Quality assurance is focuses on critical parts, important parts of quality control, the quality standards required by ISO9000 quality control procurement documents in order to clarify its status and acceptance of quality standards for company's re-inspections ; For critical parts and important that the key processes of identification and corresponding technical documentation, control by "the implementation of key quality control process", and complete, accurate and complete original records. Difficulties in quality assurance is a special process control, quality assurance is mainly painting, has developed a special process (painting) process documents, take the appropriate technical measures, to quality assurance.

In the production process, we pay close attention to quality control of each process. Every component, every process was strictly controlled. Enhanced the quality inspection process, the establishment of the necessary quality control point, the process by a full-time staff and quality inspector for inspection and supervision. Improved testing procedures and operating instruction.

OUR SERVICES

Pre-sale service

We invite customers to visit our company and communicate on technical requirements face to face. we also can do test in our lab for free. and then we will use the testing parameter to design final machine to reach client requirement.

Sale service

Responsible for debugging the equipment according to customers' requirements of various technical data. Our engineers will train our customers about equipment features and operation key points to make sure the equipment running in the best condition.

After-sale service

We provide installation, debugging, maintenance, training and other services (Optional); Provide relevant technical data, equipment, software and related GMP certification materials.

Quality promise

Our company promises strictly operate the ISO9001 quality system certification standards and pharmaceutical equipment GMP audit requirements,promise we provide new equipment. Advanced technology,good quality. Equipment operation safe reliable, affordable, easy to maintain.

Equipment warranty period is one year, all the parts for the equipment choose well-known brand.During the warranty when equipment have problem in quality like equipment failure and damage, our company offer free maintenance or replacement.